The Fan Pressure Ratio (FPR) is part of the Overall Pressure Ratio (OPR, ratio of highest to lowest pressure in your primary gas path from inlet to combustor).

The importance of the FPR depends on the application of your gas turbine, generally, higher pressure ratios are found in smaller fan diameters with lower flow capacity while lower pressure ratios are found in larger diameters with high flow capacity. Why? The larger the amount of air is accelerated at a smaller velocity increase the higher the propulsive efficiency. This is where the ByPass Ratio (BPR) comes in, this is defined as the ratio between the mass flow rate of the bypass stream to the mass flow rate entering the core.

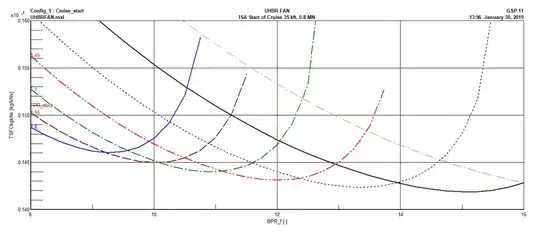

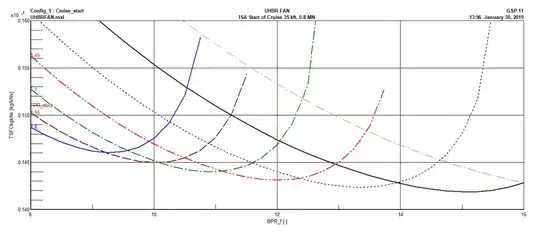

An excellent study to visualize the effect of FPR and BPR is done by Dr. N. Cumpsty in Preparing for the Future: Reducing Gas Turbine Environmental Impact. In revisiting this study for more recent engines, a gas turbine simulation tool can be used to show the effects of changing the FPR for a series of values of BPR. This can be an excellent starting point for the design of new or derivative gas turbines to find the optimum (where the Thrust Specific Fuel Consumption, or TSFC is lowest).

E.g. for a more recent (study from 2019) Ultra High Bypass Ratio turbofan engines you will get TSFC as function of BPR for FPR values from 1.6 down to 1.3 in steps of 0.05:

Basically, the FPR and the BPR determine where the optimum TSFC is for a particular engine (for a fixed technology level of your engine, e.g. choice of thrust at Top Of Climb, Tt4, Turbine cooling mass flow and OPR). If BPR is fixed, lowering FPR either increases or decreases the TSFC, it depends on your choice of BPR.

Please note that changing the FPR (or BPR) implies a change of the engine configuration (also known as the design), the tool referenced in the question only specifies TET (Turbine Entry Temperature, also known as Tt4) through specifying the FAR (Fuel/Air Ratio), preferably you want to constrain the thrust value as you need to design for a specific application/performance point. The webtool is limited and should be used wisely. Exhaust area is a calculated parameter in gas turbine design calculation/simulation, in the webtool it is a variable/scaling parameter (usually thrust is used, which is far more intuitive/practical than the exhaust area). In recreating a J85 turbojet engine it is confirmed that the webtool doesn't predict the correct performance, 20 - 40 % more is seen depending on the parameter.

Increase BPR and you'll find that FPR is now 'active'.

– Rob McDonald Mar 06 '23 at 03:13