In addition to the suggestion of using metal fluorides like CaF2, I want to mention the possibility of using carbon-based fluoropolymers like polytetrafluoroethylene (PTFE), perfluoroalkoxy alkanes (PFA), and fluorinated ethylene propylene (FEP), all of which may be sold under the brand name "Teflon", which has become synonymous with PTFE for many people. These plastics are some of the most commonly used materials for dealing with highly reactive fluorine compounds like HF, UF6, and HSbF6, as well as other reactive compounds. All these plastics are colorless, but PTFE is more just translucent, and generally looks white, while FEP and PFA are the properly transparent ones.

You can see on this chemical resistance chart that PTFE is considered "resistant" to dry F2 up to at least 60°C, as well as everything else they have data for. PFA is apparently similar. FEP is also apparently compatible with F2 up to at least 60°C: https://www.polyfluor.nl/en/chemical-resistance/fep/ That page also mentions "better gas and vapor permeability", though, which sounds somewhat worrying if you want to hold gaseous fluorine in it. However, I think "better" might actually mean lower, since this pdf of general info on FEP films from Teflon.com mentions it having exceptionally low permeability to gases and non-gases.

Some rather vague comparisons of these 3 substances are given here.

These polymers may be cheaper than metal fluorides (though I'm not certain of that), but they are not fully fluorinated, and thus can still react with F2, e.g.:

(CF2)n(s) + nF2(g) → nCF4(g)

As this page by a company selling them puts it, "[t]he extremely potent oxidisers, fluorine (F2) and related compounds (e.g., chlorine trifluoride, ClF3 ), can be handled by PTFE/PFA only with great care and recognition of potential hazards. Fluorine is absorbed into the resins, and with such intimate contact the mixture becomes sensitive to a source of ignition such as impact." That quote implies that teflon can burn in fluorine (as can normal oxide-based glass). This makes sense because I know it can burn in oxygen, although it does not normally burn in air, because "teflon" fires in the liquid oxygen tanks are believed to have been part of the cause of the Apollo 13 disaster. Also, those chemical resistance sheets I linked to list FEP, PTFE, and PFA all as "not recommended" for use with F2 at 100°C, and that Teflon.com pdf specifically mentions that FEP reacts with "molten alkali metals, fluorine at elevated temperatures, and certain complex halogenated compounds, such as chlorine trifluoride, at elevated temperatures and pressures." When combined with the fact that these fluoropolymers melt and chemically decompose into (somewhat toxic) gases at temperatures fairly typical for plastics, this means they are not very resistant to fire-like temperatures. (Thus, for example, you probably should avoid trying to close F2 in an FEP ampule by melting the tip, though maybe it would work if the F2 was in the form of a liquid far from the part you were melting. I've seen specific references to FEP being good for cryogenic temperatures and not becoming brittle, so it probably is the best for liquid F2.)

(There is a question on this stack-exchange specifically about what can attack PTFE: Is there ANY chemical that can destroy PTFE, or Teflon? .)

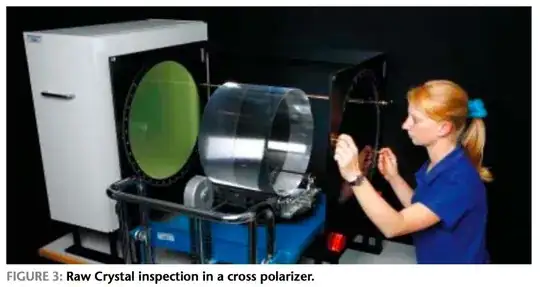

Metal fluorides, on the other hand, are much more refractory (though not as refractory as oxides). CaF2, in particular, has one of the highest melting points (my best number for the melting point is 1423°C from my CRC Handbook), though ScF3, LaF3, and CeF3 at least have higher melting points (but much lower boiling points). There is also no way for CaF2 and many other metal fluorides to be further fluorinated or burned in any way. (Some can react to form higher fluorides, which may even be gases, but there's no reason to use those.) One potential problem with CaF2 and many other metal fluorides is that they have non-trivial solubilities in water. The solubility of CaF2 in water is still very low, though, (similar to CaCO3) so I'm guessing it won't dissolve unless you leave it in a large body of water or use it as plumbing for a really long time, let it be rained on for many years, or dump acid on it. (The latter is how HF is commercially produced.) CaF2 and many other metal fluorides can be very transparent if pure (fluorides and fluoride mixtures like ZBLAN are used for fiberoptics, lenses, and windows on lab equipment), and I'm not sure if that's true of fluoropolymers.

SiO2, Al2O3, and some other other non-fluorine compounds are highly transparent, refractory, and insoluble in water, and also quite resistant to oxidation by F2. They can, however, still theoretically be corroded by F2:

SiO2(s) + 2F2(g) → SiF4(g) + O2(g)

ΔG°298K,1atm = -172.55 kcal/mol for glass or -171.13 for quartz (reaction is spontaneous)

2Al2O3(s) + 6F2(g) → 4AlF3(s) + 3O2(g)

ΔG°298K,1atm = -303.0 kcal/mol for corrundum to crystalline AlF3 (reaction is spontaneous)

Note that SiF4(g) is a gas (boiling point somewhere around -86°C or -90.3°C), while AlF3 is a colorless refractory solid (sublimation point 1290~1291°C) that might form a protective layer on the inside of a container, similar the NiF2 layer that forms on the inside of the nickel containers commonly used to store F2 and other highly fluorinating compounds. Thus, I suspect that Al2O3 is a better option than SiO2. It's possible this advantage could also be gained with "aluminosilicate" glasses (made of just Al, Si, and O), and, in any case, these probably work at least as well as fused quartz (pure SiO2 glass).

As I mentioned, melting an ampule containing F2 closed is not a very good idea, unless it's made of metal fluorides (and some metal fluoride glasses do have very low glass-transition temperatures), because both fluoropolymers and oxide-glasses react with F2 at high temperature, and may ignite under such conditions. Sealed ampules are also quite difficult to put things into or take things out of without breaking the seal. Other methods of making air-tight seals I know of tend to involve some kind of rubbery material ("elastomer", at least if a polymer). This may be used as an O-ring underneath some kind of cap or tube attatchment, or could be used to make a self-sealing membrane. I've often seen that silicones are used as these elastomers, especially for self-sealing membranes. There are fluorosilicones that may be quite resistant to F2, but normal silicone should generally be attacked by F2. Silicones all involve Si-O-Si chains, and at least almost always contain Si-C or O-C bonds, and these bonds can be attacked by fluorine. Some websurfing shows that apparently there are quite rubbery fluorocarbon elastomers, too, though. If you look at page 19 of this pdf, you can see that 3 elastomers they consider ("PERLAST®", "FKM (fluorocarbon)", and "FVMQ (fluorosilicone)") are listed as having "good" (but not "excellent") compatibility with fluorine. ("Good" apparently means they swell 10~20% when used with F2, indicating something bad might be happening.) I think the first two are both fluorocarbon-based, with PERLAST® being "FFKM", which is specifically perfluorocarbon-based, like PTFE or FEP, based on the website selling it. In any case, whoever makes the normal nickel or whatever containers F2 is sold in must have already solved this problem. (Actually, the comments on uhoh's answer point towards Halocarbon 25-5s grease as being fluorine-proof and in-fact specifically recommended for use with gaseous F2. I don't know if that's good enough by itself for a long-term seal, though.)