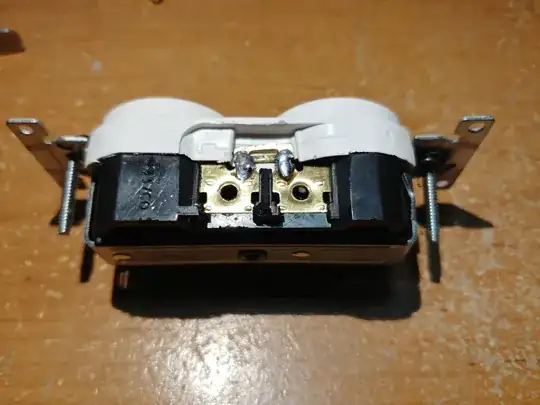

I broke the tab off my electrical outlet connecting the two hot wires, and then realized that this was unnecessary. Is it a bad idea to solder the brass tab back and still use the outlet?

- 11

- 1

-

It looks OK in that it doesn't protrude out the side. But stripping extra insulation and 1/2 loop around both screws in the same path would have been the acceptable solution. – Tony Stewart EE75 Jan 13 '18 at 01:41

-

That solder joint (butt joint, no overlap) is not acceptable. Remove the tab, run continuous wire under both screws, and it's fine. – Jan 13 '18 at 02:07

-

1Buy a new outlet they are $2.00 at the Big Box Hardware stores. The solder will last for a period of time AND it is possible over time to become what is known as a 'cold' solder joint - when that happens arcing can occur. Is this against code - to my recollection I don't think code addresses the issue directly. Spend the $2 it will correct and there will be no question about whether the solder joint becomes cold over time. – Ken Jan 13 '18 at 02:59

-

1@Ken a joint doesn't become cold over time. It's either cold when you solder it, or it's not. Afaik. – cde Jan 13 '18 at 04:00

-

1Solder only connection is a code violation. Get a new outlet a cheap builders grade under 2$ a nice spec grade 5-7$. – Ed Beal Jan 26 '18 at 19:11

-

@cde Many (and I do mean MANY) people refer to a broken solder joint as a cold solder joint. Regardless of whether this fits the actual definition by the book, it is generally understood that a solder joint that is no longer making a good connection is a cold solder joint. (tomato, tamatoo) – noybman Jul 06 '19 at 18:44

3 Answers

Into the trash goes this 75 cent outlet

It was wrecked by removing the screws and soldering the tab.

Soldering like that to alter a device is not a proper wiring method and is not safe. Solder does not conduct as well as copper, and melts much sooner. Edit: Here's a link that shows solder has 9x the resistance: copper 0.0168, solder 0.145. As soldered it has no chance of carrying the required current. Keep the solder in the electronics lab.

If you hadn't also pulled the screws out, I would say just unsolder the tab (you're not allowed to modify devices like this) and put 2 pigtails on the 2 screws. You join those with a wirenut to the two wires you would have otherwise attached to those two screws.

However since you've also torn the screws out, I would say toss the receptacle in the trash. They cost 60 cents, or $3 for the really good ones.

Those screws are captive, meaning when they are most of the way out, they get really stiff. You're supposed to stop turning at that point. That is a detent designed to keep the screws attached for your installation convenience. Pulling them out damages their threads. If the receptacle has features like screw-clamp, removing the screws "loses" the clamps and ruins the receptacle.

So now you know in the future: anytime you're loosening a screw and it gets weirdly stiff most of the way out, that is a mechanism trying to keep the screw captured. Don't do a "gorilla act" on it.

- 300,628

- 26

- 286

- 734

-

just a FYI: solder in today's world is made of silver and that is a better conductor than copper. The outlet in question - less than $2 buy a new one is the best answer - pig tailing and wire nutting adds another set of wires and a wire nut - I am guessing space requirements in the receptacle box still apply. Of course he could claim he repaired the device and did not modify it. This is a spend $100 to save $1 question. So your point about buying a new one and being done with it should probably be in BOLD .. your other comments are good information +. – Ken Jan 13 '18 at 03:09

-

@Ken There is no silver in solder commonly used in electronics. Silver solder is a specialty item. – Barry Jan 13 '18 at 04:04

-

@Harper - I'm with you. Consider the labor. Labor is time and time is money. How much would it cost to replace a device that will work perfectly or repair a device that might work for a short time. In short, unless there is a specific need to repair a device, just replace it. – Retired Master Electrician Jan 13 '18 at 14:44

-

@Barry in today's world it is not difficult to find. RoHS compliant products have pushed this, along with the growing tentacle issues with Tin - silver solder is easily available ( however it is combined with other materials - such as tin so quality varies) . https://www.amazon.com/TrakPower-Rosin-Silver-Solder-ounces/dp/B007KN0FD2 – Ken Jan 13 '18 at 23:30

-

Silver is only very marginally better than copper, not better enough to justify using it unless you happen to have an entire fortress full of the stuff lying around doing nothing while copper is in war demand and you need to make thousands of cyclotrons on the sly. Regardless, "silver solder" isn't enough silver to make up for the poor conductivity of the other alloys. You just can't vouch for a re-soldered "tab" having the same conductivity, and if it has less, it will be prone to melting at its very low melting temp compared to copper, and then dripping slag. – Harper - Reinstate Monica Jan 14 '18 at 00:20

-

5@Ken I just found a link that reports solder is 9x worse a conductor than copper. Silver solder isn't really silver, it's like 3% silver. – Harper - Reinstate Monica Jan 26 '18 at 17:11

-

Meh, silver, lead, gold (its a amazing conductor!) The importance here is that while solder can make a sound electrical connection, it is not intended for long term install and forget high current carrying high heat generating connections ever; regardless of material. Code doesn't allow it for significant safety reasons. This was a cool question I hope others stumble upon in the future and people avoid solder at all costs (pun intended). If you broke the tab on a fancy $300 outlet, pigtail, or buy a new outlet. – noybman Jul 06 '19 at 19:09

Don't solder it. Just use an extra wire between the two sections, preferably through an appropriately sized twist on cap. While solder may work, your introducing it in a way that will likely void your home insurance policy if a fire starts.

- 709

- 3

- 14

-

4

-

@solar why? Nothing about using a wire to tie two independent outlets together would go against standard practices. – cde Jan 13 '18 at 01:00

-

3There is nothing wrong with connection the two outlets with standard wiring, but since the image posted in the question shows the outlet has already been soldered, it is best to throw it away and replace it. Any electrician who happens to see that would be justified in saying that an unqualified person has been tampering with the wiring. – Jan 13 '18 at 01:30

-

@Ryan Hackney In case of a fire the inspectors search the ashes. Their job is to find all possible excuses to reject the payment. If the house isn't totally yours, the other owners do not thank you if an electrician happens to find your solderings and reports of their existence so that the other owners see you have already kept the insurance cancelled an undefined time. – Jan 13 '18 at 01:48

-

3They are also as cheap as dirt.. why bother messing around with it. https://www.lowes.ca/electrical-outlets/legrand-15-amp-125-volt-white-indoor-duplex-wall-outlet_g1193642.html – Trevor_G Jan 13 '18 at 02:02

-

If you run an extra wire between the two sections, you have used up all the capacity of the screws, and have no ability to add any more wires. You cannot place 2 wires on a screw. There are the backstabs, but well, it's leeegal but we recommend you do not use those. Anyway, this outlet is scrap now that he's removed the screws. – Harper - Reinstate Monica Jul 06 '19 at 17:36

Looks neat and reliable but not kosher to inspectors.

I did the same thing, once in my 1st rec. room 30 yrs ago until I realized they used these for wall switched light fixtures outlets.

The dimples retain the wire from getting squeezed away from under the screw.

Someone handy with a needlenose can do an insulation strip in 2 sections on the same wire.

- 602

- 3

- 10

-

$2 buys a new one.. no questions, no worries ..cold solder joints can be very bad and do happen over time. Captive screws do not fall out either.. – Ken Jan 13 '18 at 03:11