Yes, I know I can go to the big box store and buy lumber. That is not the point of this question.

I have some boards that have the nail heads removed, leaving the nail flush with the surface of the board. The boards come from pallets where apparently they used a sawsall or cutoff blade to reconstruct the pallets several times:

Side view:

Close up view:

After prying them out, I see tiny wires around the outside (my guess is to actually prevent removal ... what are these nails called?):

https://diy.stackexchange.com/a/27821/81954 gives some hints on how to remove nails, but relies upon the head being somewhat close to the surface. But in this case, the heads are sheared or sawed off flush with the surface.

Since this is for shop use (not fine furniture), and I don't need to preserve the whole width of the board (but do want to preserve the length), I have been cutting a notch into the wood about 1/4" deep, and chiseling the wood out just enough to get a ViceGrip around the nail, and then slowly prying up the nail and ViceGrip with a long crowbar. I can subsequently rip off the edge of the what is left over of the board and reuse most of the board.

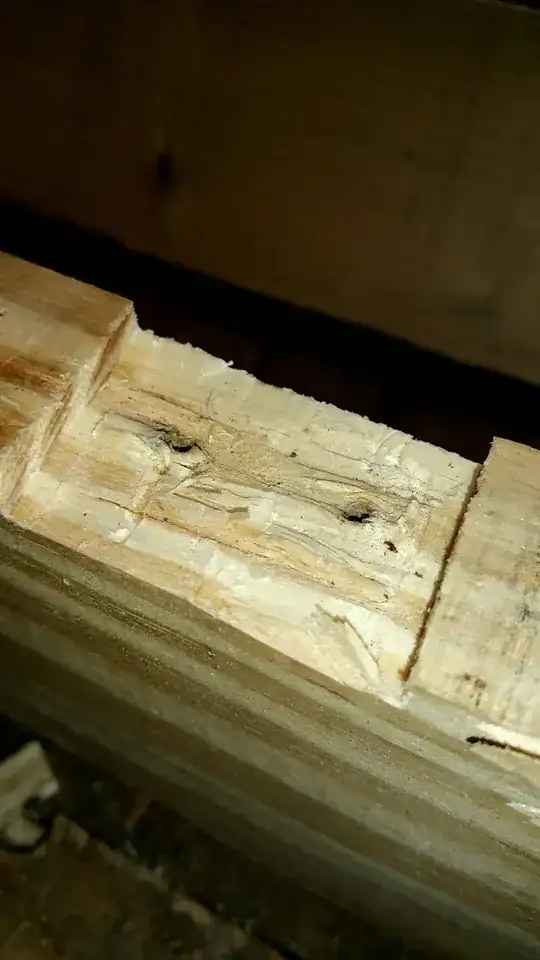

Here is a view of the result after I've pryed out the nail:

That works but is time consuming.

Is there a tool that would both dig into the wood and around the nail, and have enough gripping force (similer to what I can get with the ViceGrip) to allow me to then pry out the nail? The "Nail Jack" style of tools are close but they don't have the toggle-bolt gripping action of a ViceGrip and lack a way to hammer the chisel edges into the wood deeply enough to grip the headless nail body.

How to remove these nails (no access to head)? seems like it would be applicable, but it is not.