I'm building a small bridge over a creek on my property and using some forest service plans which recommend 8x8 ground contact lumber kept in place by earth anchors for the sills that the bridge stringers rest on. It's not out of the budget to use the 8x8s, but to move them in place might be a little difficult with the machinery I have access to (basically none). If the main force on these is a downward pressure, could I substitute four 2x8s stacked and attached together at bridge site? The only concern I could think of would be water penetrating between the boards and causing them to decay faster.

Edit: the 8x8 (or built up beam) would be fully laying (lying? ) on a solid bed of compacted gravel (or concrete) and anchored using a duckbill anchor. Since none of this is suspended in air, I don't think deflection of the beam is a concern. However, it's possible that it'll be completely submerged in water at flood stage, which happens 1-2 times per year and lasts for less than a day.

Edit #2

Here is a link to the page with the plans I'm using with some modification (just adding railings and using more stringers). https://www.fs.fed.us/t-d/pubs/htmlpubs/htm12232316/.

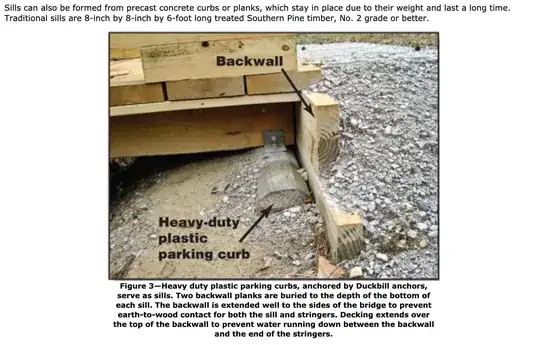

Below is an image that illustrates the sill. In this image, they have a heavy duty parking curb, (which is a possibility to use but those things are heavy and I don't have easy access to a machine to easily move them), but they specify that an 8x8 pressure treated southern pine could be used.

I do understand that a laminated beam spanning an opening should be vertical boards, but in this case, I thought the horizontal stacked approach might be ok and just make it a little easier to handle it as I do it myself.

Thanks!