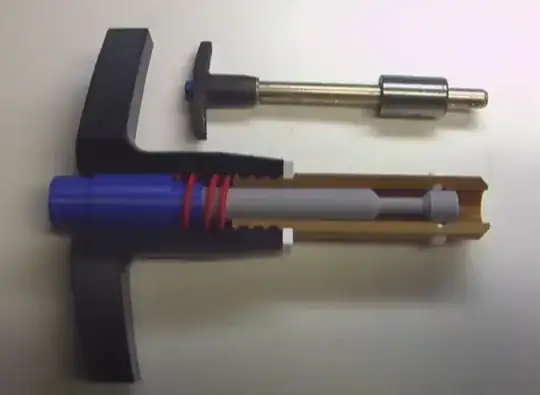

The kind of quick-release pin shown in the picture has a cap with an interior thread so it can be removed from the pin which has an exterior thread, revealing a center rod that extends axially down through the pin. My question is this: is the center rod a single piece that reaches down to the balls to cause them to protrude from the surface of the pin, or does that rod consist of two pieces, a long rod and a very short piece abutting it at the bottom that forces the balls outward when the center rod is pushed down into the pin?

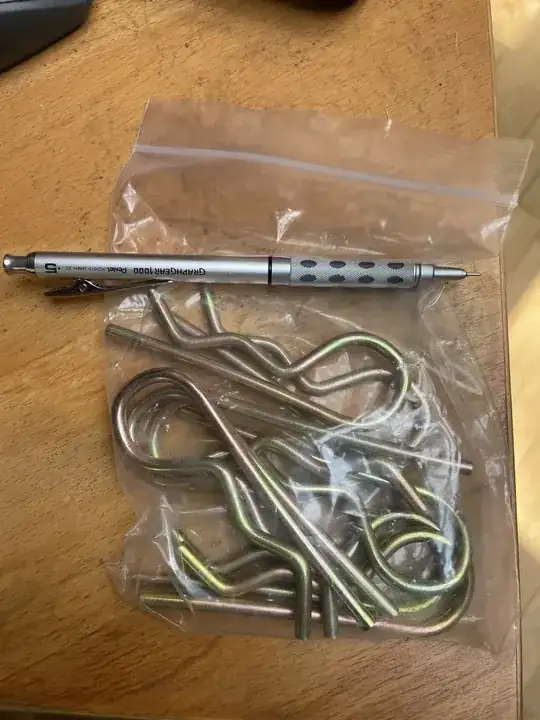

The DIY connection, I want to make a cement mixer's barrel easy to remove from the motor shaft so I can power-wash the inside after using it. The motor isn't supposed to get wet but has no protection against water ingress. The unit ships with a large 12mm diameter pin and a cotter pin.

P.S. If it weren't for the fact that the drum is rotating, and over the course of the 360 degree sweep there are some pieces of the motor mount that are in the way if the clip has twisted slightly, these clips would work fine. I mangled one when trying them out for this purpose.