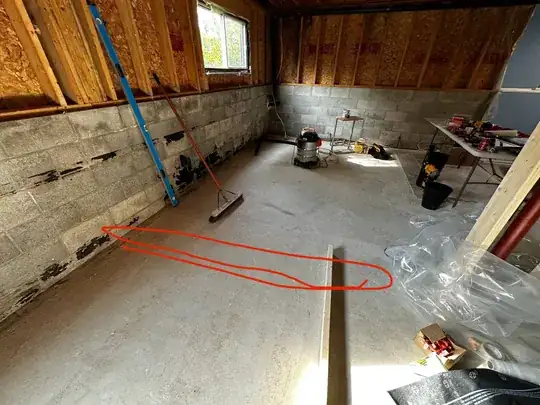

Simply attach the knee wall to the concrete floor and the concrete/block stub wall, exactly the same as if you were attaching them to wooden framing. The only difference is the kind of fasteners you'll be using.

To attach to concrete, you'll use a concrete screw or anchor bolt (Tapcon™ is a well-known brand of concrete screw and RedHead™ is a well known version of anchor bolt no affiliation with either brand, no recommendation intended or implied). These will require drilling appropriate sized holes in the concrete and precisely lining up the holes in your lumber to match. Alternatively, you could use a powder actuated nailer to directly drive nails through the wood and into the floor.

To drill the holes for screws or anchor bolts, you'll really want to use a rotary hammer. If you don't have one, they're commonly available for rent at dedicated tool rental locations. Many big-box retail stores also offer tool rentals. If you choose to go this way, lining up the holes really isn't that difficult. Lay out your bottom plate (use pressure treated lumber since it will be indirect contact with concrete), lay out your stud locations, then mark and drill through the bottom plate with a regular wood drill bit. When you hit the concrete, you can push a little more to make a mark in the concrete of precisely where the hole is. If you're not leaving a mark or worried about destroying a (cheap) drill bit, you could use a quick shot of spray paint directly on the wood and into the hole to make a mark on the concrete. After you've drilled and marked all your holes, move the bottom plate and drill the holes with the proper size bit using the rotary hammer.

Do the same for the stud (use pressure treated here as well) that will attach to the wall.

Note that you only need PT lumber for the boards that will be in direct contact with concrete/masonry. The rest of the wall can be built with non-PT lumber.

Important Note:

If you have hydronic (in-floor radiant) heating, you either need to know exactly where the in-floor piping is (and avoid it), or use construction adhesive to attach things to the floor. Drilling willy-nilly into your floor is an easy way to puncture the in-floor tubing, flooding the basement and requiring an expensive repair.

Thanks for the reminder Mazura!