Looking for advice and/or affirmation of my thoughts. I have read other posts and nothing quite fit just perfectly for the direction I am looking to go. But I might be over thinking this.

I am about to wire up a shop/garage in my backyard, clearly LOL. The electrical wire distance from my house's load center to the shop's predicted load center location is 160'(+/-5ft) including up and down walls. I have 200-amp service to the house. I would like 150 amp to the shop. I haven't quite settled on a shop load center location but it will be within the 175'.

I basically have no equipment bought yet, I have read a lot of others posts about buyer regret from not researching first, and at least learned some wisdom from their mistakes. I did get some breakers form an estate sale but didn't find out that breakers were manufacture specific AND series specific. Unfortunately, they are Square D homeline breakers, but it was a buck a breaker so... But I've digressed.

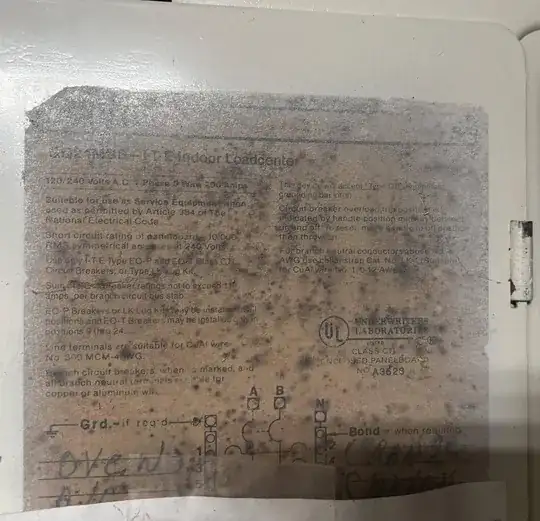

I am going to be upgrading my house's load center (currently an unknown brand) as it is 25+ y/o and more than came with the house in 1980. That coupled with some house electrical rewiring and additional outlets, best to replace it.

I have been eyeballing the Square D QO plug on neutral load center 200-amp for the house's replacement and the Square D QO 150 main breakers plug on neutral load center for the new shop setup.

I am considering URD401000 - 4/0 Urd Sweetbriar Alu for the wire from house to shop. I am open to arguments for copper verse aluminum, but the cost was, of course, cheaper. Also, the direct burial makes it easier for me as well. I have considered 1/0 Cu THHN (and 4awg THHN ground wire?). My house is located in the county, so codes apparently allow for the direct burial Ai. Cost isn't the top priority, doing this correctly is, but cost is still a part of the calculous, of course. I am willing to trench and grey PVC conduit some THHN. Have shovel, will travel.

Is there a better load center I should considering? Is there a reputable manufacture with pass through lugs available that don't cost an arm and a leg like square Ds? I only chose square D because my other shed has a QO series in it (hence how I discovered that the series matters just as much as the manufacturer when I tried to use the breakers, I got so cheap.). I despise GE products in general, so I avoided them. I have a siemens for another load enter but I haven't been all that impressed with the prewire job that it came with inside for RV hook ups.

I need a separate ground rod 5/8" by 8'. I can't put the rod Stright down (solid rock about 3' down so I plan on a horizontal 30" deep placement with 8awg wire to the shop's panel. Do I need two still? I read somewhere that it needs to have 25 ohms resistance, or it you need two at least 6ft apart. how do I measure the resistance? the soil is dry and cracked so I would figure I have infinite resistance right now.

These are the questions battling in my head. I sure I have missed something in the other posts I read, I just wish I had more experience. So, what am I not covering and missing in my designs? Am I going the correct direction or am I all over the place and need to reassess my concepts? Thanks in advance.

I found this QO2150

As a side note, the shop will be future proofed for EV charging, RV power (50 amp 240), and support for a 4.0-ton AC (30 amp I believe), as well as the obligatory shop 120 psi 80 gal air compressor (30 y/o Cambell Hausfeld but still worthy) and probably a small welder at some point. I do realize that I am approaching max load with just those items running at the same time but realistically by the time I am forced to get an EV I won't have the 5th wheel anymore. and even then, the 5th wheel doesn't use the max load even when cooking and using both a/c units I'm still only at 40amps total between each L. and what are the actual odds of all those things kicking off at the same time, as I write this I know it will happen now.

I had an electrician over (for a different project) who mentioned connecting my shop power to the secondary lugs on at the meter enclosure (the meter enclosure is sperate from my load center and on the outside of the house opposite of my load center which is on the inside of the garage. How do I determine if this is plausible. I say the tamper seal... I was tempted to just cut it and take a peek but haven't yet.

Thanks again