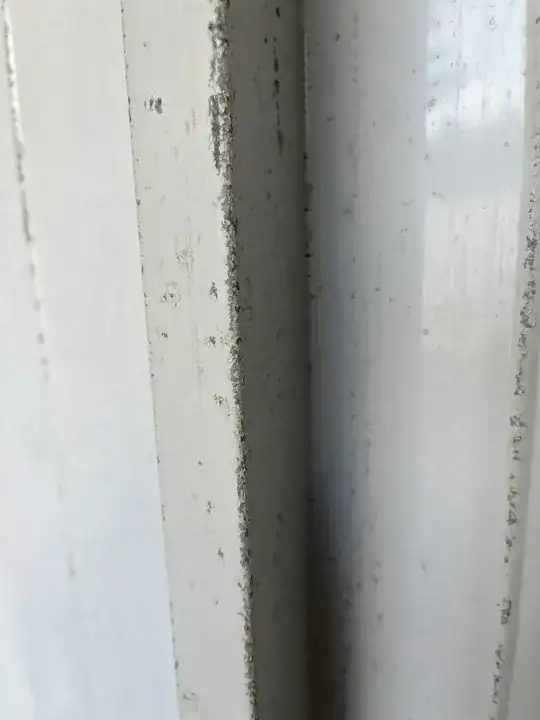

Think of an empty soda can with somebody standing on it. Poke the side of the can and it instantly crumples. This phenomenon is called "local buckling." Pushing and pulling on the steel flange with a French cleat will antagonize your steel studs analogous to poking the side of the soda can.

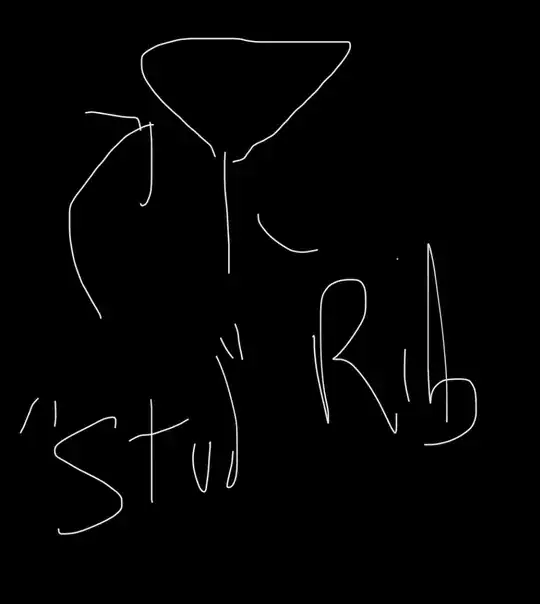

I would install a 1/2" or 5/8" chunk of OSB to the inside surface of the steel studs, and then I would attach the French cleats to this OSB. For fasteners between the OSB and the studs, I would put 1 #8 fastener down low and 3 #8 fasteners up high with 2-1/2" space between fasteners in the group of 3. I would attach the French cleats to the OSB at points midway between studs to distribute loads between studs as much as possible.

Hopefully the group of 3 fasteners will spread any pulling on the steel flange to minimize the possibility of local buckling up high. The OSB bearing against the steel flange down low should eliminate the possibility of local buckling down low. If the group of 3 fasteners lands at or near the stud's midheight, then I suggest increasing the height of the OSB to get that fastener group away from midheight (the soda can heuristic rationalizes this to my mind). The French cleats can be installed at midheight without negative consequences, however.

I don't invoke your intended loading because who knows how the system will be abused in the distant future. The best you can do to push back against such abuse is to size the group of 3 fasteners as a structural fuse that breaks under abuse. That level of complexity for some tools in a shed seems silly.