I'm designing a red oak table with 3" thick legs. I haven't found anywhere local where I can source 3" thick red oak boards, and the cost would probably be prohibitive anyway. So I thought I'd make them out of some leftover plywood that I'll have from the tabletop.

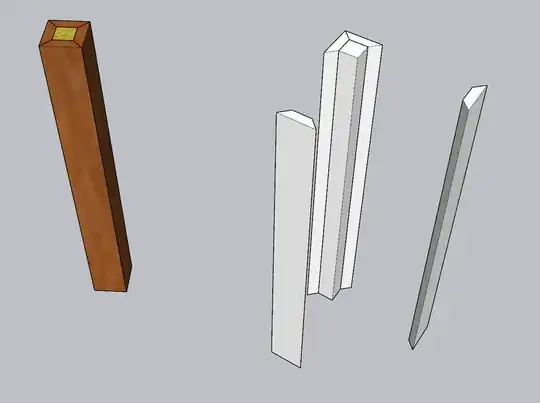

Here's what I'm thinking of doing:

The core could be two 1.5" strips of plywood glued together, two solid oak boards, or a cheap piece of 2x2.

I'm pretty new to woodworking, so I'm not sure if I'll run in to problems with this design. I know that getting the miters and the gluing perfect will be difficult, I'll have to do several test runs with scrap wood first (if 'difficult' is a understatement, let me know).

I found this site that describes an almost identical process, so it seems doable at least, though they're using solid wood in that article.

I own a table saw, miter saw, and router, but I don't have a jointer or planer.

Will these legs be durable if made this way? Does it matter if I use softwood for the core, or should I stick to oak core? Is there a better or easier way to make thick oak table legs without access to thick boards?