Needs to be food safe, durable and easy to clean. I know that beech is a good material to use as I have a beech chopping board at home, but would it make it even more durable / easy to clean by oiling the board e.g. with mineral oil?

No. What it will do is introduce a 'finish' that never dries and needs to be topped up periodically for the entire service life of the boards. As bizarre as it seems it's also very much not waterproof. Beyond that, from an aesthetic point of view wood oiled with mineral oil looks permanently like it's damp, instead of having a truly finished look like you'd get from an actual wood finish.

So instead I would recommend polyurethane, specifically a thin wiped-on application of anywhere from three to six coats with drying time in between. Varnish is perfectly safe for direct food contact once fully cured (source: regulatory agencies worldwide).

I have no problem in general with laminating timber up to give large/wide boards, but do I need to use a special glue for use with food?

Not really, but some glues are almost universally recommended in this sort of context, including Titebond III. (Note: the actual quote on their site in regards to the food-safety issue is this, "Titebond III Ultimate Wood Glue and Titebond II Premium Wood Glue have both been approved for indirect food contact.")

Given that they are such wide boards and will be getting washed/wet do I need to make any allowances to stop the boards from warping, twisting, cupping, joints separating etc?

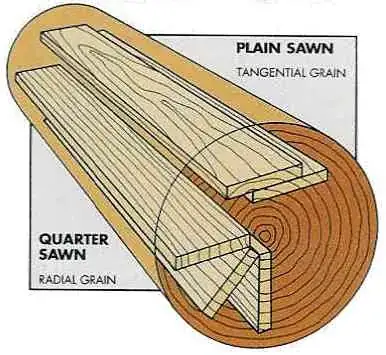

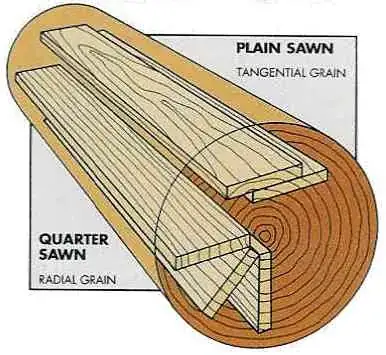

I would recommend selecting your stock carefully so that you're exclusively using quarter-sawn boards, where the grain is oriented vertically or nearly so on the board ends:

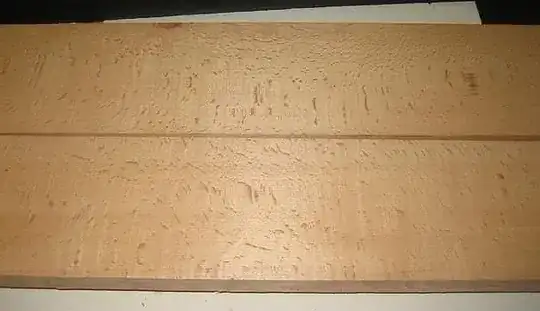

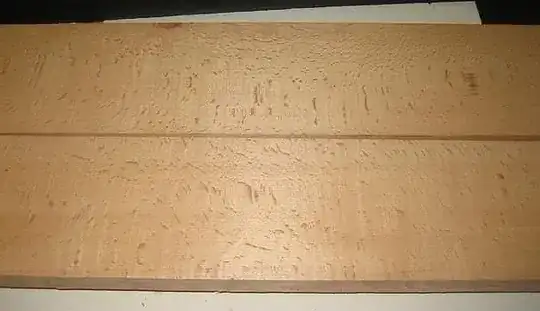

As you can also see from the drawing, quarter-sawn boards also feature straight, uniform grain on their faces. Additionally in beech, as with oak, there's also the possibility of "ray-fleck" figuring on the board faces which some people find very attractive.

Quarter-sawn wood is more stable than plain-sawn/flat-sawn wood:

I can easily insert dowels, or biscuits, or use a finger joint block to give increased surface area.

Believe it or not, none of those actually materially improve the strength of a glued-up top. At the end of the day they primarily function as alignment aids during assembly, which are unnecessary if the clamping operation is done right (e.g. using cauls).

Would it be better to use a minimum amount of timber pieces e.g. 3 off 200 x 600mm boards glued up to make a large 600x600mm board, or will it be better to use a higher number of narrower boards which are 600mm long, or an even higher number of boards e.g. 50mm x 200mm with some end-to-end gluing? Presumably this may help with stability,

Many narrower strips can end up stronger and more stable than a basic glue-up of wider boards (think glulam), however there is some dependence on the wood as always. Very stable wider boards could make a perfectly serviceable product, particularly if quarter-sawn wood is selected for the reason shown above.

How long can these be expected to last if being used once or twice a week just for serving food, without being used for any chopping?

As far as the customer is concerned: indefinitely.

Some upkeep will be required but the wood itself has a service life measured in decades at least, centuries at best.