Now I know that I can just buy these in packs of hundreds likely but lets play pretend that I need to make some from what I had available. When I think of fluted dowel I picture these guys...

Image from HomeDepot.com

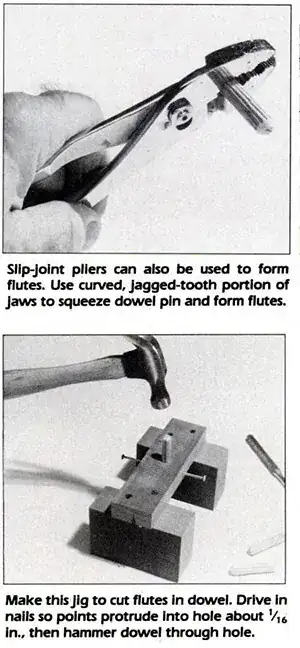

That style of dowel would be difficult to emulate. I am not going to make a jig where I would rotate the dowel and run a beading moulding plane, or similar tool, to scratch a groove in. If they are actually compressed maybe I just need to compress them with something? Is there another method of working the dowel that will get a similar functional result?