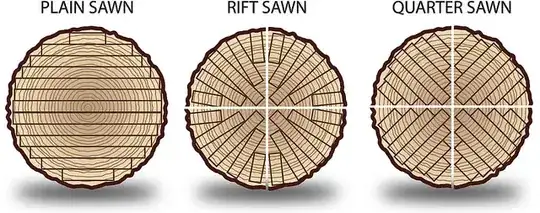

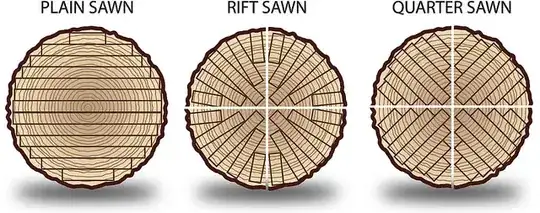

In its basic form quarter sawing is a method of processing logs into lumber. It is one of 3 common methods: quarter, plain/flat, and rift sawing.

Image from Flickr. Note that there are many other cuts that exist but still fit in same general categories

Image from Flickr. Note that there are many other cuts that exist but still fit in same general categories

Plain

Also known as bastard sawn, through and through, and tangent sawn. It the most common way to mill lumber and arguably the cheapest. The log orientation is not typically moved during this process. The widest boards are made in this way since you cut across the entire diameter.

Rift

Rift or radially sawing produces the most consistent strength across all boards since each board is cut perpendicular to the grain. Commercially, it is not common as there is a lot of waste wood. Custom woodworkers milling their own logs may use this when making furniture, for example. Visually all the boards look very similar giving projects the same look and feel.

Quarter

Quartersawn (quarter-sawn) or quartered sawn is with the rings 90 degrees to the face. The quartered sections are individually cut with not attempts to waste wood. The block can be rotated repeatedly so the saw will remove the wider portions of the quarter.

More Reading

- Advantage Lumber

- Quarter Sawing. Covers other cuts briefly.

- Canadian Woodworking

Important

It's important to understand that, while named the same, the milling processes and resulting boards are two different things. It would be easier to say that each of the milling processes can yield boards of different types. There is confusion that stems from this. Quarter sawn has changed meaning over time:

For more reading look at What are the different uses for plain sawn (flat sawn), rift sawn, and quarter sawn boards? for more explantion of the different milled boards and how to identify them.

Image from Flickr. Note that there are many other cuts that exist but still fit in same general categories

Image from Flickr. Note that there are many other cuts that exist but still fit in same general categories