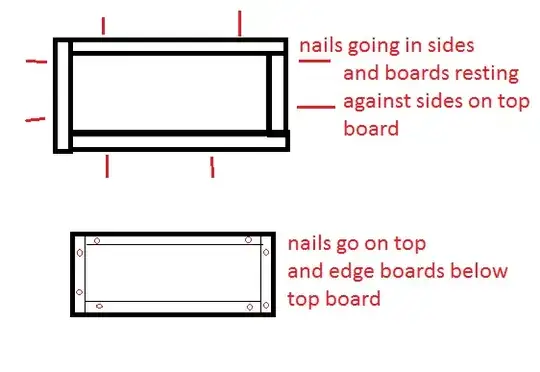

I'm making a end-table topper out of 1 3/8" butcher block for over the top of a subwoofer. I posted a question about how to route out the center of a board. It was determined that although it is possible to route out the interior of the massive board, attaching an edge board would be the path of least resistance to create the end table top.

Given the scope of my prior question, I decided to open a new one.

Which is the standard practice of attaching the edge board? Which might be the most cohesive with butcher block? Would glue or nails or both be better? If nails and/or glue, what kinds?

There are a lot of options, and it really boils down to preference.

– Jacob Edmond Nov 16 '16 at 20:21