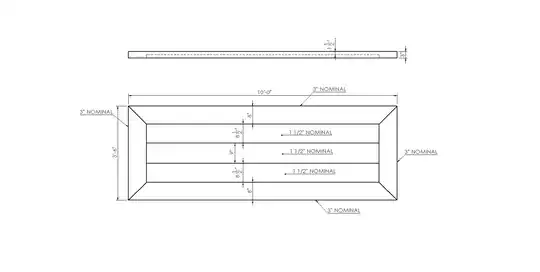

My main question is this. I plan to use 1 1/2" nominal boards in the middle of the table to reduce weight and material costs. If I miter a frame around the thinner boards with the 3" stock and join/glue it all together, will the thinner boards expand/contract at a different rate and cause the top to crack or warp?.

Thinner and thicker boards expand equally pretty much, for any given type of board (rift, QS or flat-sawn). The issue with this isn't differential movement, it's movement period.

Let me pass on verbatim a piece of advice from a pro that I read a couple of years back:

resist the urge to picture-frame a tabletop.

There's nearly no way to get this to work properly with the glued-up centre panel. You could just about get away with it using the right wood (QS mesquite being a rare example) but with most other woods you're asking for trouble and both oak and mahogany (all types) are no exception.

At maximum expansion the central boards will have no problem at all breaking apart two or more of the mitre joints, even if they're reinforced with biscuits, splines or Dominos.

If you managed to secure the mitres somehow so that they couldn't be broken open (e.g. by using metal fixings) the central panel will be put under enormous strain when it tries to expand but can't, and the result then is warping and/or cracking.

Getting the look without the drama

Probably the best way to do this is using plywood or another board material for the central panel, with veneer applied if necessary.