Stanley/Bailey #4 w/ corrugated sole, #5 1/4, #6, Wood river low angle block plane, Stanley sweetheart dual rabbet plane, Simmons #6--longer than Stanley/Bailey #5 but smaller than #6).

Which of these planes would be best for a shooting board?

Any of them other than the rebate plate.

Which size of plane to use for shooting is partly a matter of preference. Some like to shoot with a no. 4 because they're smaller and easily controlled with one hand, others prefer to use a plane that has more mass so use 5s or larger.

Note: for shooting board ends it can be very advantageous to use a larger plane because the greater heft can't as easily be stopped in its tracks by the resistance of the end grain in harder hardwoods. But sharpness of the iron and plane settings play a role here too — the sharper the iron is the better, adjust for a light cut, cap iron should not be positioned ultra-close to the edge.

Is there some trick to grinding the edges square to the sole?

You can get it much closer using the common lapping technique used these days of rubbing the plane back and forth on abrasive paper or cloth. The trick to improving squareness is that you can lean more heavily on the sole side or the opposite and you'll slowly remove more material there, beginning to bring the cheek to square. Then you just need to slog away until you're done (remembering to stop frequently to check for square).

You can also do this work with metalworking scrapers and file work. This requires some practice to get good results (filing in particular) but metalworkers tell us both are better for achieving a truly flat surface on a plane.

But however you tackle it it's actually not important to do on almost any plane.

The cheek doesn't need to be square to the sole

The lateral adjustment on a bench plane means that if the sole is slightly out you can compensate for it by adjusting the tilt of the iron assembly until its cutting edge is square to the sole.

And most planes will have cheeks that aren't so far out that this is possible.

Not critical even when jointing

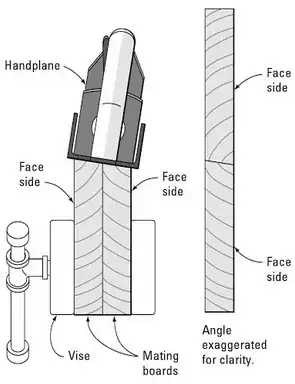

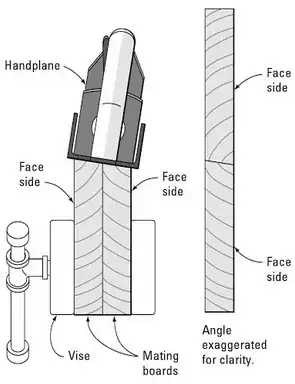

If doing edge shooting for jointing purposes (making glued-up panels) it's not vital that a board's edge ends up perfectly square to the face, as surprising as that sounds. What matters is that the edges of each pair of boards are complementary angles. So if one edge is 89° and the next is 91° they'll meet just as well as if they were both at 90°.

In order to ensure that each pair of edges is at a complementary angle you simply need to plane one of them face up, the next face down.

Here's a picture that may help if you're having difficulty in visualising this. It's for hand-planed edges but the same principle applies (this is also applicable to using a powered jointer incidentally):

Source: The Complete Illustrated Guide to Joinery by Gary Rogowski.

If you can plane dead square, by hand or in a shooting board, that's great, but as you can see you don't have to sweat it too much if you don't.