Should I worry about movement for this type of tabletop at all or can I just screw it fixed?

Yes, you always have to consider wood movement with components made from solid wood. And the larger the pieces are the more important this is because the total movement is greater.

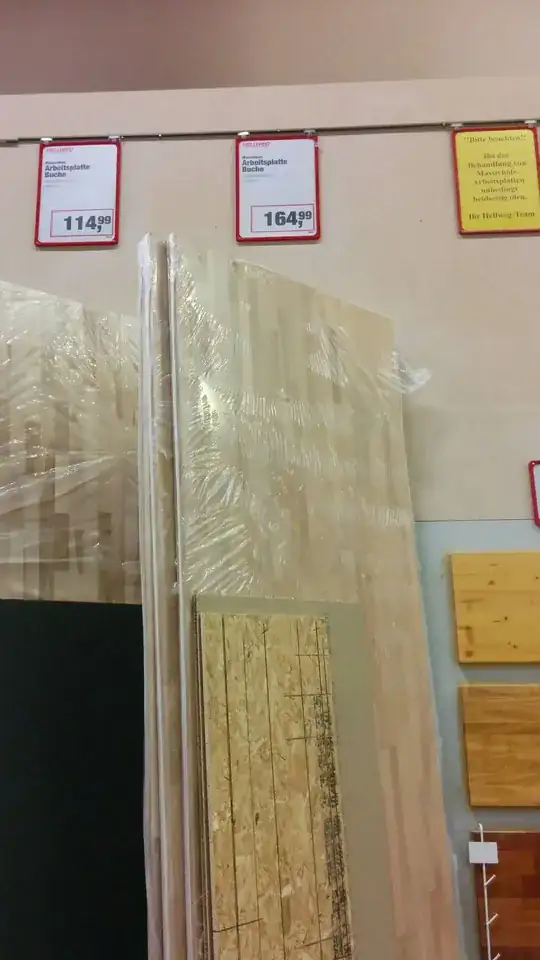

In addition you have a greater concern because this is European beech, Fagus sylvatica, because it is subject to greater changes in dimension that many other woods — double that of some pines, triple that of iroko! So the this top could change width by more than 2cm (an inch for Imperial users) between the wettest part of the year and the driest part of the year in a climate with wide swings in humidity.

The problem is that none of the methods that I've read about that allow for movement are compatible with the screw holes facing up in the frame.

I hate to say it but I think that's because that leg framework just isn't designed for a solid-wood top. The movement here could easily exceed the small amount of play of those screws in those holes (in fact I think this is likely based on my guesses of the dimensions), which would at least begin to work the screws loose after a few cycles of expansion and contraction. In extreme cases this type of strain can snap screws in half before they pull free.

It's not too difficult to work around the problem however. If I were doing this I'd lengthen those holes slightly* to make them into short slots oriented 90° to the long sizes of the top. Then I'd install the screws with washers underneath their heads to spread their load and allow them to slide more easily.

*Using a carbide burr in a drill or a round hand file, depending on how tough the steel was.