I have an Irwin-Record 9½ block plane which I bought new a year or so ago and have been using and occasionally sharpening the blade on an oilstone. Now the blade-depth adjustment has reached the end of its travel.

When I adjust the blade depth wheel to the other end (fully retracted blade) and move the blade to the next position, the blade protrudes too far - about 1mm depth of cut. The only way to make this work seems to be to grind down the blade significantly which doesn't seem right.

What might be wrong and how can I fix it?

Update following scanny's answer:

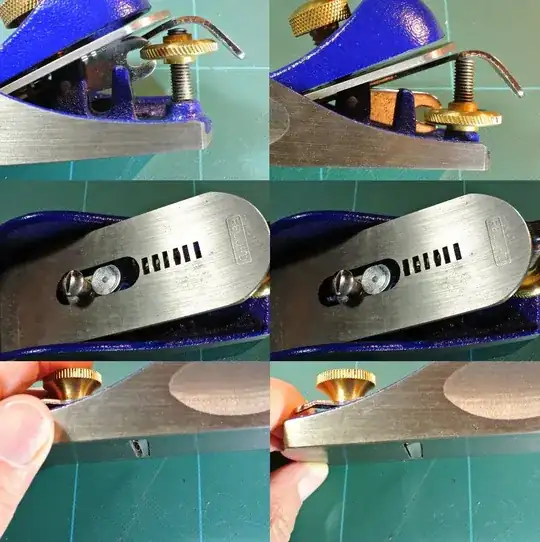

Using a vernier caliper, the travel of the fine-adjust tooths without blade installed seems to be about 3mm. The spacing between front edges of all but one of the slots in the blade is about 4mm, so this looks like a design flaw. Maybe Irwin (or their far-away 3rd-party manufacturer) substituted a blade design to save costs somehow?

In fact, looking at it, only the first couple of slots can be used before the end of the long slot in the blade hits the lateral adjuster.

Older Record blades and the current Ray Iles replacements only have grooves on the rear rather than through-slots and they may have been more finely spaced. I only have this photo to go by:

If the long slot in this blade is the same length as that in my Irwin-Record blade (34.3mm), the adjustment grooves are spaced 3mm (centre to centre) and so are a better match to the fine adjustment travel.

Using a dial indicator (as suggested) I measured the travel of the blade installed in the plane when moving the adjustment wheel from top (deepest blade position) to bottom (highest blade position) I measured a total movement of only 1.95mm - say 2mm. This is less than the 3mm travel in adjuster tooths which I measured when the blade was not in place.

(Plane is clamped down, subdial of indicator shows just under 2mm movement = 2 rotations of main dial for full travel of plane's adjustment wheel. Click for larger image)

This is partly because at the top position, the pivot arm hits the underside of the blade before the adjustment wheel reaches the top of it's screw. There's also a large vertical clearance gap between the adjustment wheel and the edges of the corresponding slot in the pivot lever in which the wheel sits - so part of the wheel's travel doesn't move the lever, until the wheel reaches the other side of the clearance gap.

Given the spacing of the adjustment slots is 4mm, I can't see how this blade can be moved to the adjacent slot and positioned ready for use without grinding the blade down by 1 or 2 mm.