I'm a "weekend woodworker" (boxes, small shelves/cabinets, stuff like that). Now I'm thinking about replacing one of my wardrobes, and was thinking about doing it myself. The problem is: in Romania, solid wood is actually cheaper than processed wood (MDF, plywood, etc) with veneer faces (because I want an overall natural wood look).

My question is (I didn't find anything concrete searching here or on the internet):

When making solid wood furniture, do I need to worry about the wood cracking because the different faces expand at different rates through-out the year?

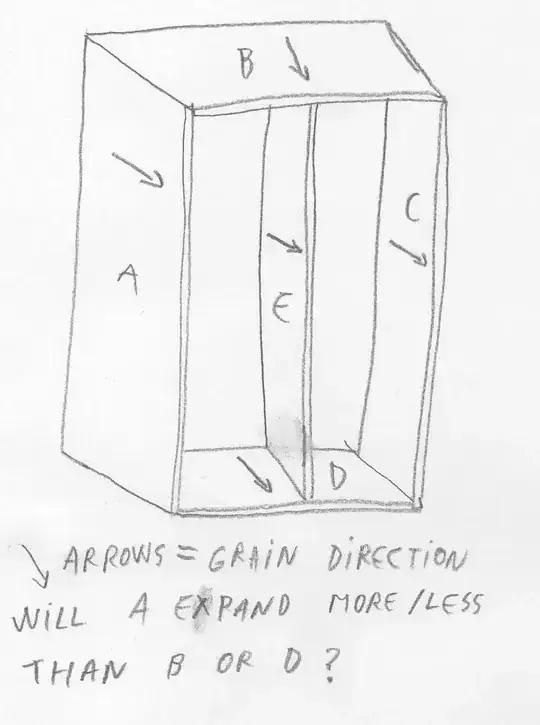

More explicitly, if the sides, top, and bottom planks/faces will be screwed to each other, will the planks expand/shrink at different rates, thus making the wood susceptible to cracking at the screws? They, of course, will be from the same type of lumber, with the backing from plywood. But even so, I'm worried one of the planks will expand more/less than the adjacent ones and put a strain on the screws.

I'm thinking about making it either from oak or more possibly walnut, 2m (6.5 ft) height, 1m (3.2ft) width with divider in the middle, and 0.7m (2.3ft) depth. So the faces/planks will be about 2*0.7m (6.5*2.3ft).

Any info/hint you can give me will be much appreciated.

EDIT: Since I am clearly misunderstood: if the grains are running in the same direction, will any of the faces expand more/less than the faces next to it, thus cracking the wood?

(please excuse my crude drawing, I am in a hurry) Thanks.

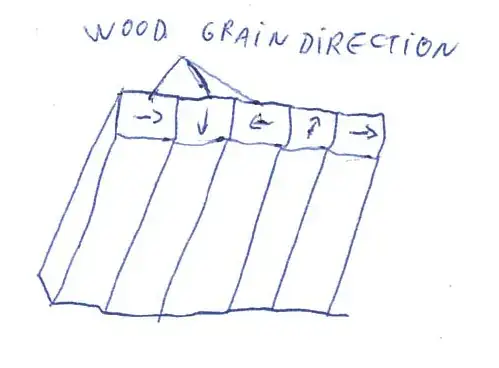

EDIT2: would it be better if I made my own boards/planks from quartersawn lumber (I can easily get it in 1.8*1.8cm (0.7*0.7in)) with each piece turned 90 deg cw (thus making the grain in each plank run in all directions, which if I understand correctly, will make it more dimensionally stable)? Or would that just be even worse? (elbow grease and tools are not a problem. I have enough tools / friends with tools, and I'm not skittish about work...I actually like working with my hands on projects like this :) )