- Have I done anything wrong?

Not that I can see. The simple truth is that a commercial product made from kiln-dried wood should basically never exhibit cracks after it is installed in its final destination, even if left for an extended period of time with no finish on it1.

- Will my desk eventually crack and collapse?

I doubt complete failure is possible with stave construction, but it's impossible to predict what's going to happen in the short and medium term.

You'll have to monitor and see if the problem progresses, or if the wood has settled down and done all the cracking it's going to. As mentioned in the Comments, I was going to suggest marking both the location and the extent of all the cracks on the underside. That way you'll know for sure if A) new cracks form and B) if the existing cracks get longer. In either case alarm bells should sound.

There are some who would say you should enquire about returning this now. I would at least investigate the possibility, explaining to the vendor what has happened and see what they say; they should NOT tell you that a few small cracks (of this kind) are normal! They aren't. I've seen dozens and dozens of examples of this type of glued-up panel in beech and birch (hello Ikea) and in oak (other furniture, kitchen countertops) that have no post-finishing cracks that I could see. Ergo I don't think it's a matter of opinion that these are not normal or to be expected, and that more than a few pieces of the wood used in the construction were flawed in some way2.

If more cracks appear and/or the existing cracks continue to grow then I think asking for a replacement or refund is definitely the right call.

- Can and should I do anything about this? (E.g. fill the cracks with glue, finish the underside.)

Assuming the wood is done cracking, you can probably safely live with any of the cracks that don't bother you, especially the ones on the underside.

Most of these cracks appear superficial but even more major cracks in one or two of the staves should not be structurally significant because of the method of construction, where the affected pieces are surrounded by strong glue joints and other pieces that are stable.

If you did want to fill the cracks on the top, you have various options but note that anything that involves glue will pretty much guarantee you'll need to refinish the top3.

I won't cover the how-to aspect of filling but will quickly list all the fillers that I think are currently available:

- Wax filler — various kinds, softer types are basically like crayons but a better option for a working surface is one of the harder types that need to be melted in.

- Shellac filler. These are much harder that almost all wax fillers, and also need to be melted in.

- Glue + wood dust — the ideal glue for this not being PVA glues.

- Superglue and sanding dust. I mention this separately because you don't normally mix the filler and then apply it because of the very fast setting time of superglue.

- Shellac + wood dust. This takes a surprisingly long time to dry hard but can make for nearly invisible fills of fine cracks and gaps in joinery that will subsequently be finished in the same shellac.

- Straight epoxy (high on my list as the best option).

- Commercial wood fillers.

__

1 Something that is actually extremely common in commercial kitchen installations for example, where the panel may arrive on site days at least before installation, and after the install the counters may sit unfinished for weeks, and sometimes far longer. Also worth bearing in mind that the bulk of such installations are to houses where building is still in progress — with plaster still drying, and no heating.... so the short time you had it on your terrace should have zero bearing on this.

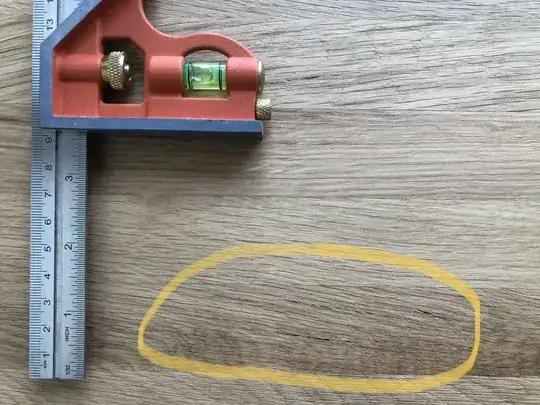

2 I suspect improper drying — possibly left too wet (so the wood is now drying and shrinking), or dried too quickly (leading to defects). The last image in particular, those appear to be 'surface checks', which the textbooks tell us are a drying defect.

3 Since you used shellac which is very repairable you might think you wouldn't need to do the whole top, and in theory small repairs can be done and seamlessly blended in. But it's best practice not to locally sand small areas of a large flat surface (because making shallow depressions are virtually inevitable). This will lead to a slight, but perceptible, waviness that you may be able to feel, but will surely be able to see in raking light or when light is reflected from the polished surface.