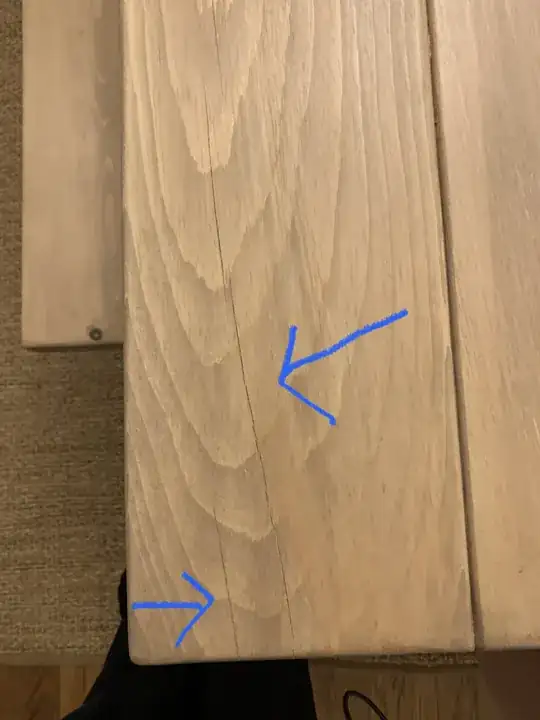

The main problem is the way the wood is cut ("flat-sawn"). If you look at the tree rings in the end grain for that particular board, they probably look like a "U", in which case the bottom part of the U contracts/expands more than the top part as moisture decreases/increases. This is because wood moves most across the grain within each ring (as opposed to along the grain), and the outer rings have more surface area. It's this difference that causes a crack to form, and this is why it's a good idea to alternate the directions of the U's when gluing up flat-sawn boards for a panel. Increasing the moisture in the room might help close up the crack temporarily, but unless you're able to completely seal the board from moisture, especially the end-grain, you'll have a recurring problem any time the moisture in the room changes. If the crack gets larger, you could try to fill it with a mix of sawdust and wood glue and then sand down. Once it's filled in, you can stain or oil the table to help seal it. Or if you like the unfinished look, at least seal the end grain of the boards with some oil or wax.

Edit: To answer your questions, "Is this normal?" Yes and No. Yes, it is normal in wood if the end-grain of the wood is not properly sealed, and the piece of lumber has strong curvature in the rings, it is normal and to be expected if the environment undergoes changes in moisture. No, it is not normal in inside furniture kept in a reasonably stable environment, since most furniture will reach an approximate moisture equilibrium where changing internal stresses are not enough to cause checking. "Will the cracks close up if I increase the moisture in the room (leave the fire off, run the humidifier)?" Possibly, but this would not be a permanent or long-term solution to getting rid of the cracks, as future changes in moisture can cause them to open up again. Also, if you overdo the moisture, then you could have cracks open up on the opposite side of the board as it warps the other way.

Edit 2: I took a few pictures of plain-sawn wood in my shop from reclaimed furniture that show similar cracks, just to refute the notion that what is not normal for some might be normal for another. I only have a few examples right now because I avoid stripping/refinishing plain-sawn wood pieces exactly for this reason---once the finish is stripped, they tend to warp and crack as they adjust to the moisture. Happy to post if there's interest and someone can walk me through how to upload them to this site.