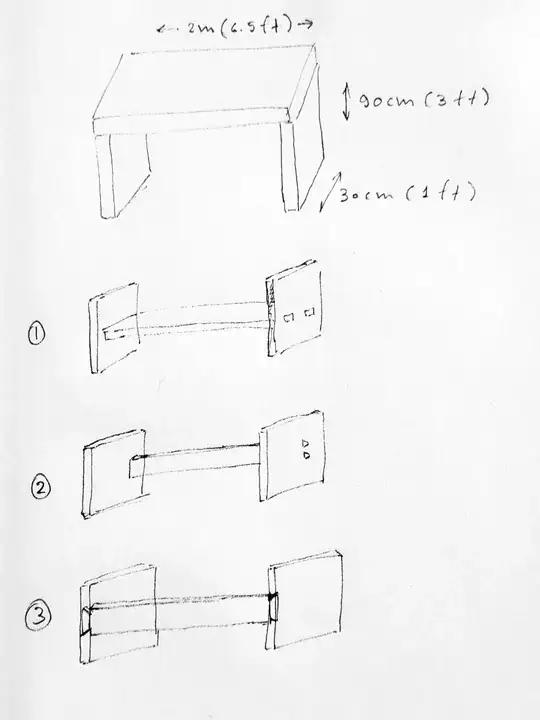

I am building a console as shown below (not to scale). The boards are 5 cm (2 inches) thick pine. The sides are joined to the top using dovetails.

I have not assembled this yet but I am concerned about racking. What would be a traditional / time-tested way to reinforce something like this?

I have thought of three options:

- A shelf attached with dadoes & tenons. This seems right, but I am not sure it will be useful as a shelf, and if not, it will take up more space than other options.

- A reinforcement bar with a vertical cross-section. Is a mortise & tenon joint appropriate here provided the bar is small?

- A dovetailed reinforcement bar on the back. Would this work w.r.t. wood movement? One advantage is that I can add it after the initial glue-up.