Do pocket hole screws allow for proper expansion and contraction in planked table tops?

It completely depends on where they're sited. They're perfectly acceptable in some places and utterly wrong in others.

Refer to this previous Question, What general considerations do I need to take into account for wood movement? for more info on that regard with some more useful info in this Answer.

Anywhere a pocket screw (or any other fastener, or glue) restricts the ability of cross-grain wood joints to expand and contract as they need to with changes in internal moisture content you have a problem — either the fastener has to give (breaking or bending) or the wood has to give (breaking free of the fastener or if it can't bowing and/or cracking overall). Slightly off-topic: this is one reason that some hammer-and-nails carpentry can appear to break the rules, it's because nails allow for some movement in part because they're mild steel and can bend a bit.

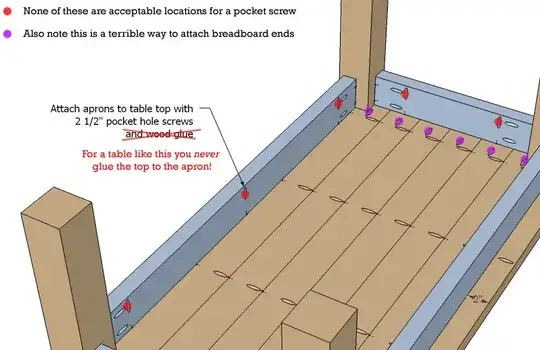

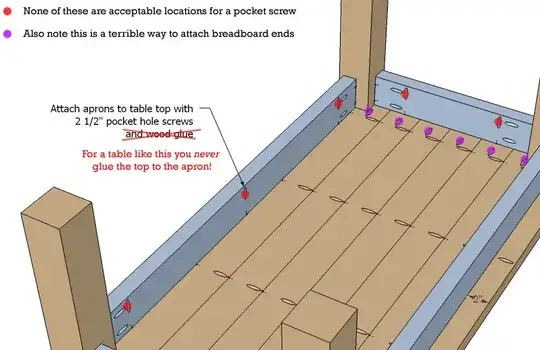

To give a specific example for anyone who has trouble visualising where pocket holes work OK and where they're a bad choice I'll take a section of the image posted by grfrazee and highlight the badly placed ones:

Note: in the long apron that trio of screws would be matched by another trio on the facing apron, that's why they're not suitable. In only one apron you could get away with it... assuming the top were not glued down and screwed in place rigidly as this plan calls for!

I am now converting to using fasteners, such as table buttons, Z-clips, etc., to attach the table top to allow for expansion and contraction.

In case it's of help, my two favourites are shown in this Answer.