Expansion/contraction-wise, I do not believe that securing of the five boards running end to end will cause a problem. This is basically the same condition as if they were glued together, their primary movement will be to expand and contract towards and away from the center to the sides of the table top. A problem could arise where the breadboards are secured to the ends of the table top boards. Since the table top and the breadboards at each end are oriented perpendicular, their movements will oppose each other. (Boards expand along their length at a much smaller rate than across their width or height)

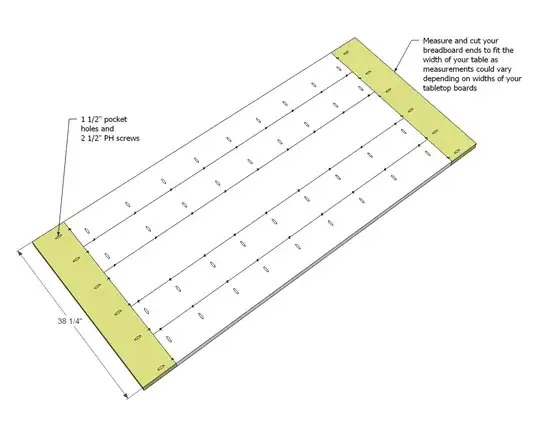

Breadboards are basically secured firmly to the top only at the center. The boards at each side of the center are held in place vertically in a keyway (or by using biscuits etc.) and allowed to slide in the breadboard to and from the sides. The ends of the breadboard are secured to the table with screws in slotted openings so that some lateral movement is still possible.

In order to work well, the expansion of the table top boards must be accommodated within the individual pocket holes of the breadboard. The center of the breadboard is firmly affixed to the breadboard and movement occurs towards the sides. In fact the maximum movement occurs at the outside edges. The total expansion across the top will be from the center to each edge or approx. 19" of wood width. Figuring a little conservatively the expected expansion here would be 14" x 5 (percentage range of moisture variation) x .003 (expansion coefficient from wood tables online) = .21" or slightly less than a quarter inch on each side (nearly 1/2" across the width). That means that the pocket hole at the outside edges must allow for up to 1/4" of movement in the hole in the breadboard, which is a lot. Note that the breadboard edges must be long enough to absorb this width expansion. Now the screws at the sides will be able to turn at an angle within the pocket hole in the breadboard, but the movement at the edges will be enough to shift the shaft of the screw beyond the edge of each pocket opening. If the screw strikes the side of the pocket hole it will resist further shifts as the top expands.

Some other considerations that might help the detail include:

- Use a wood type with lower expansion coefficient than .003, The table below is taken from popular woodworking.com at this link. Note that Q/S is the coefficient across the growth rings and F/S is with the rings.

The humidity differential of 5% reflects a total variation in humidity expected in its final location. If it is going to be in an air conditioned environment it may have lower variations.

Do not assemble the table when humidity is at the highest or lowest points. This will maximize the overall expansion and contraction. If it is assembled at its middle range it will still have the overall movement calculated, but only half in each direction. In our calculations above this would result in a movement of 1/8" each way at the sides of the table.

Also keep in mind that the movement range occurs seasonally and the joints will have a tendency to work further loose over time. Screws in the wood will not provide as good a connection as a traditional breadboard detail. In addition the screws will not resist the tendency of the top to warp and curl as well. The slotted connection of a traditional breadboard provides continuous alignment of each board in the top. The screws can only hold alignment at screw locations so cupping of individual boards in the top will eventually show themselves. That is unless you provide a slotted groove in the breadboard and tongues in the top board edges. In that case you are almost all the way to a proper breadboard anyways, so why not complete it as such?